Our History

Ringarooma Tin Dredging Company

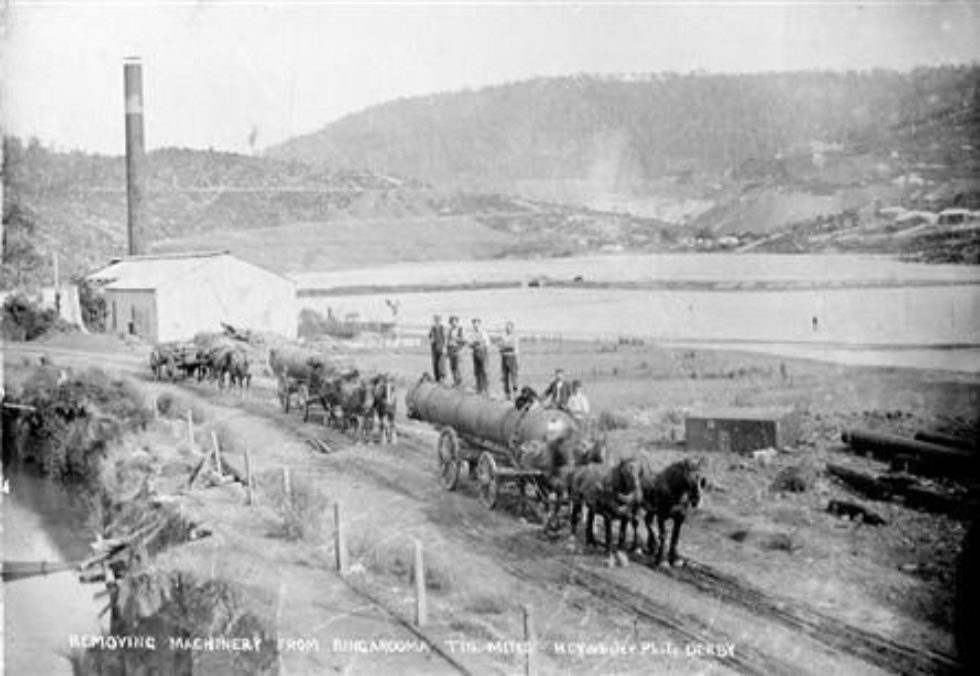

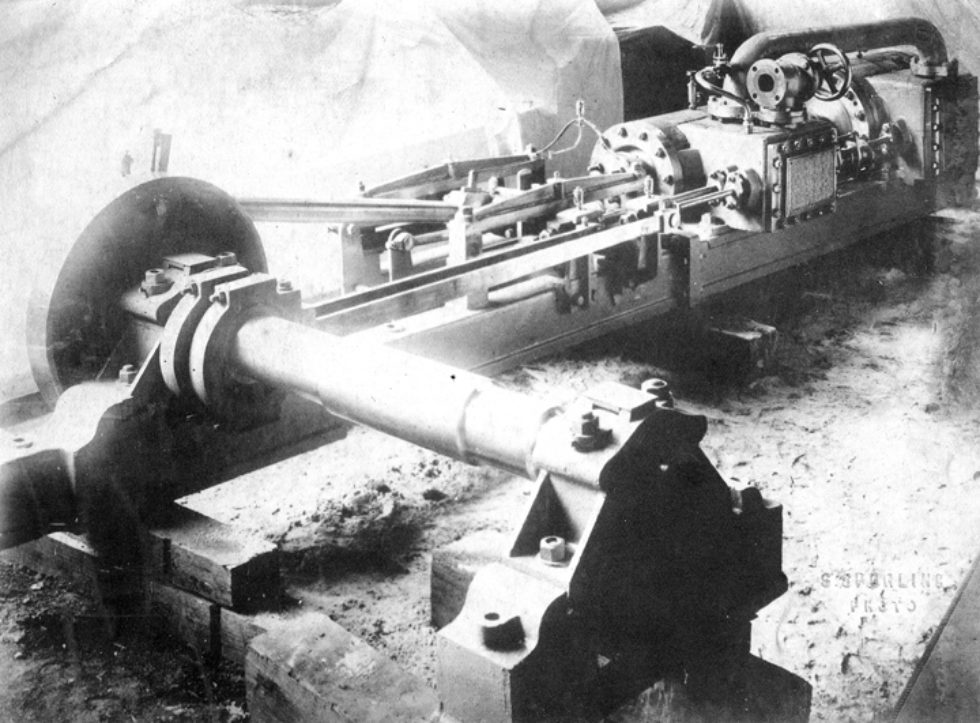

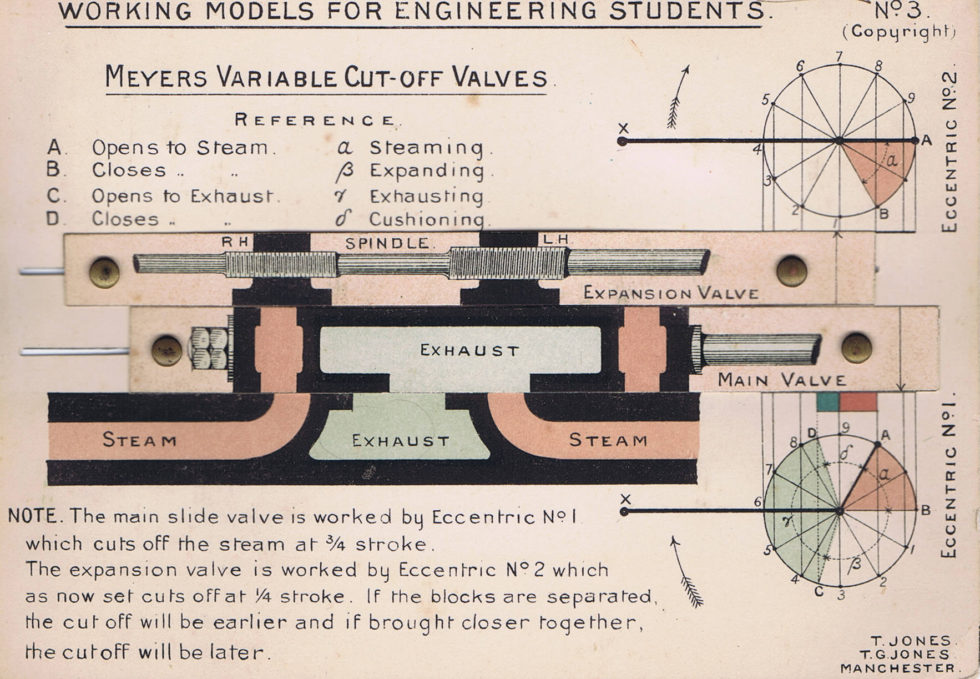

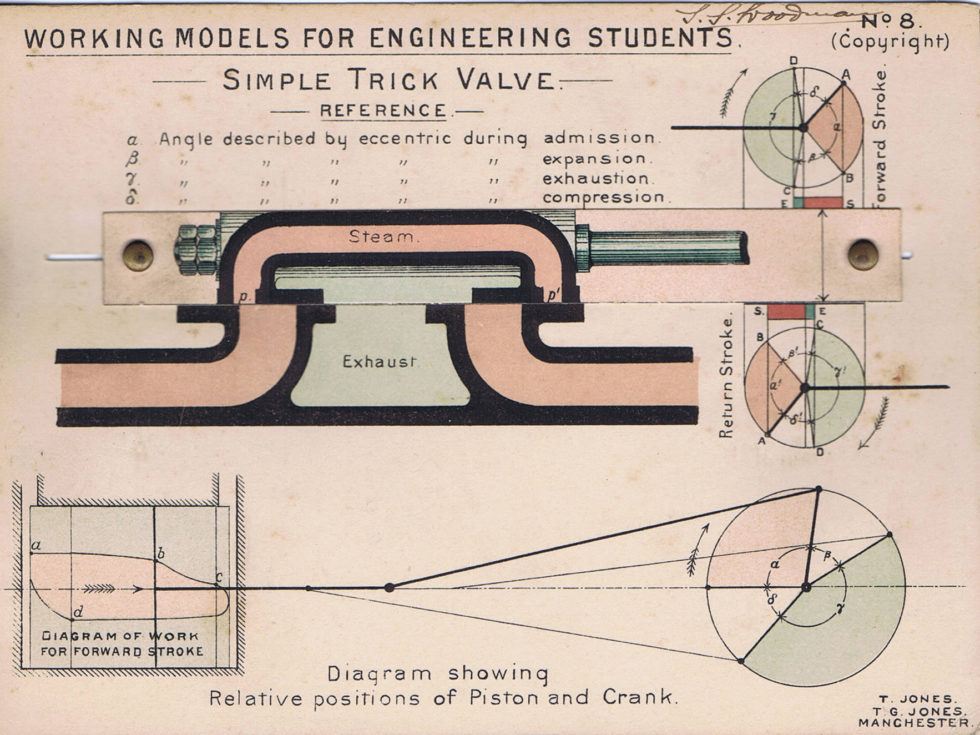

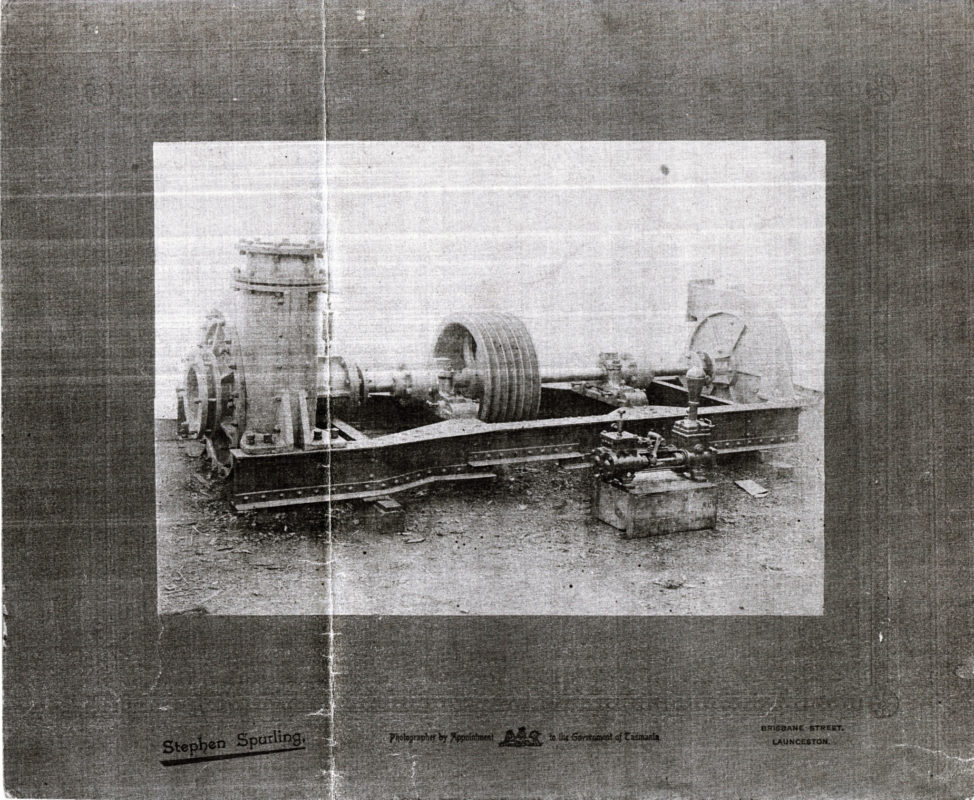

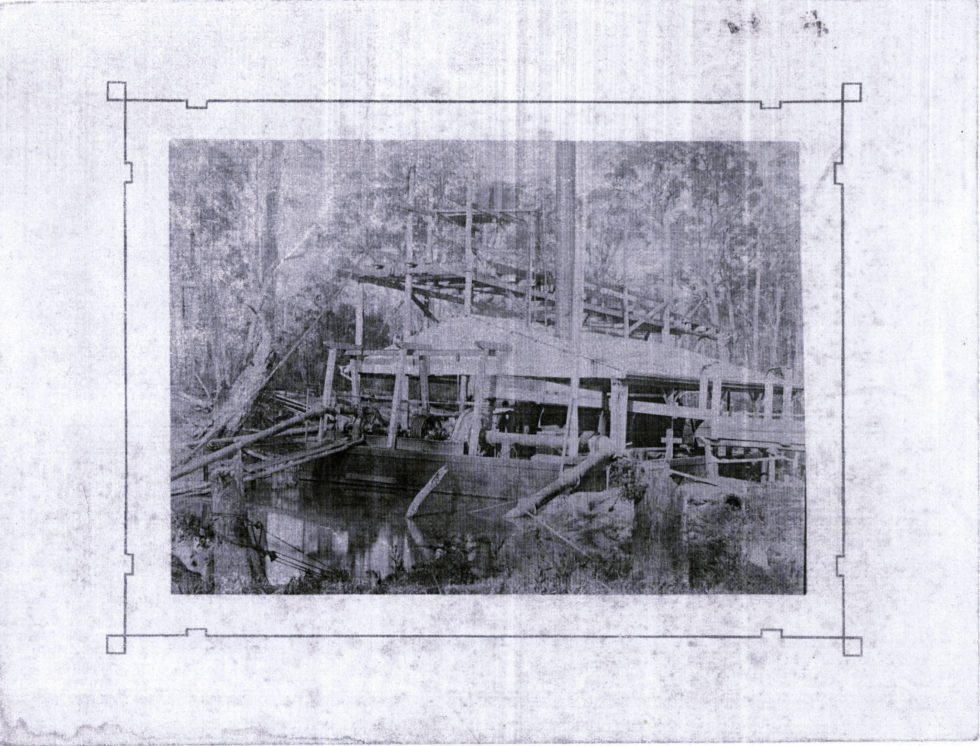

In May 1899 the Ringarooma Dredging Company contracted Bogle and Clark for the construction of a barge and suction dredging plant similar to those that were successful in operation at Campbell's Creek and Yackandandah, in Victoria. This contract comprised of a barge 50 ft. by 40 ft. by 5 ft. draught, which was constructed from Oregon planking over hard wood frames, on which was erected the required machinery. A gravel pump that had a suction and delivery of 12in., and was be capable of raising 100 tons of material per hour. A powerful sluicing pump was also supplied for breaking down the material and conveying it to the gravel pumps. The gravel and sluicing pumps were of the most approved up-to-date design for this class of work, all the wearing parts were provided with hard iron and steel liners, while the shaft and runner of the gravel pump were protected from the wearing action of grit by a water service supplied under pressure from a special Tangye pump. The sluice boxes were 110 ft. in length, 5 ft. broad, and 12 in. deep, made from cast iron, the first 25 ft. of which had venetian ripples and balance plates. The power for driving the above was derived from a tandem compound condensing engine, having cylinders 12 in. x 19 in., with a stroke of 24 in., and was designed for high speed, with extra large bearing surfaces. The high pressure cylinder was fitted with Meyers's variable expansion gear, and the low pressure with a Trick valve. The engine was capable of indicating 150 horse power. The boiler was of the compound Cornish multitubular type, being 6ft. in diameter and 20 ft. in length, this was constructed entirely of steel, with the required heating surface for 150 h.p. The sheet and furnace plates were 1/2in. thick and the ends were 5/8 in., there were 74 3in. boiler tubes, and the scantlings and staying were for a working pressure of 120 lbs. per square inch. Under very tight time constraints Bogle and Clark had made substantial progress with this project. The building of the barge was entrusted to Fred Moore. This had been formed up, marked and taken to pieces in Launceston before being shipped to Boobyalla and then on to South Mount Cameron, where it was erected and completed. At the foundry operations were being carried out briskly, two shifts of men were employed at this time so that the work was carried on without interruption day and night.

Unfortunately Bogle and Clark were never paid in full for the work done and the Ringarooma Dredging Company folded due to poor returns. Under a writ of fi. fa. - fi. fa. stands for fieri facias (a writ ordering a levy on the belongings of a debtor to satisfy the debt) Bogle and Clark vs. the Ringarooma Dredging Company, No Liability the defendant company's leases at South Mount Cameron, 350 acres in all, together with a dredging plant, tools, etc., were sold by auction at the Court House. Bidding went up to £ 55, at which the lot was knocked down to Bogle and Clark.