Our History

Boral Timber

During January 2000 Glasgow Engineering were invited to attend a meeting with Boral Timber at their Long reach mill site, with the idea to design and construct a device to aid in the loading of wood chips into the hold of a ship. The issue they were experiencing was by the time the ship had arrived in Japan the chips in the hold of the ship had compacted, in some instances down by six feet, quite a loss of potential income. After a few meetings and a combined input from Boral Timber and Glasgow Engineering a proposed design by John Hutton was agreed on and we commenced work on the project.

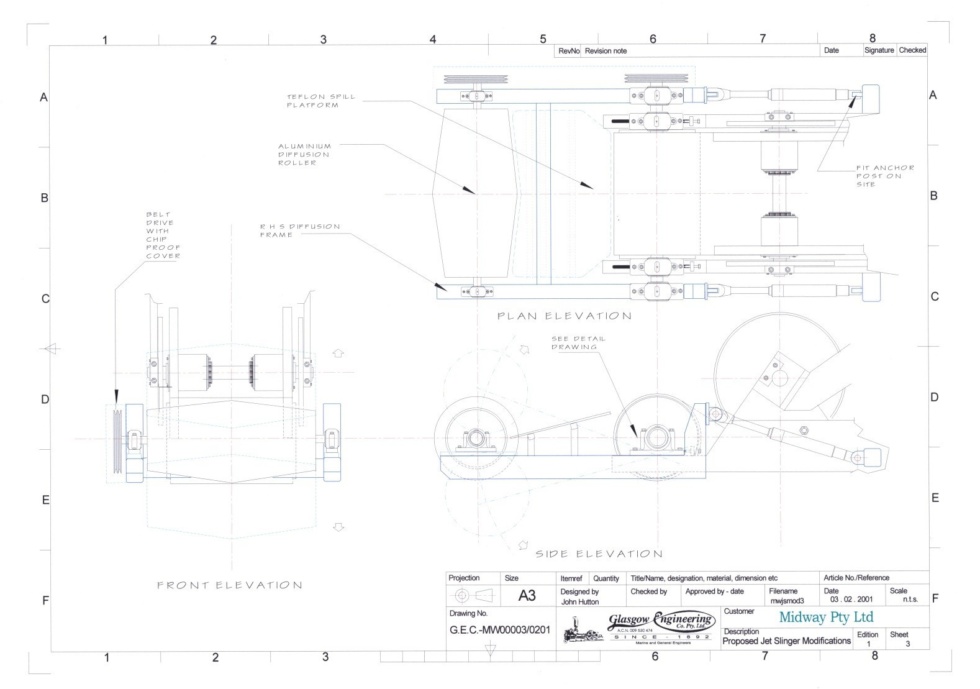

The design consisted of a spinning conical roller mounted at the end of the jet slinger which could be raised or lowered into the stream of wood chips as they left the jet slinger.

The idea behind the spinning roller was to diffuse the impact of the chips as they left the jet slinger to land into the stockpile of wood chips in the ship’s hull. This caused the wood chips to flutter upward, making them land flat. That in turn had the effect of increasing the compaction in the hold of the ship by up to 3% and also aided in flicking the chips up under the vessels hatch coamings during loading. That 3% had the potential to make a big difference in a million dollar ship load.