Our History

APPM Wood Chip Mill Longreach

During 1984, continuing maintenance work for the woodchip mills at Long Reach, kept Glasgow Engineering’s work shop’s busy. Regular jobs such as the refurbishment of the Bellingham Barker trunnion shafts, and the large blower from the ship loader required ingenuity and expertise to be undertaken.

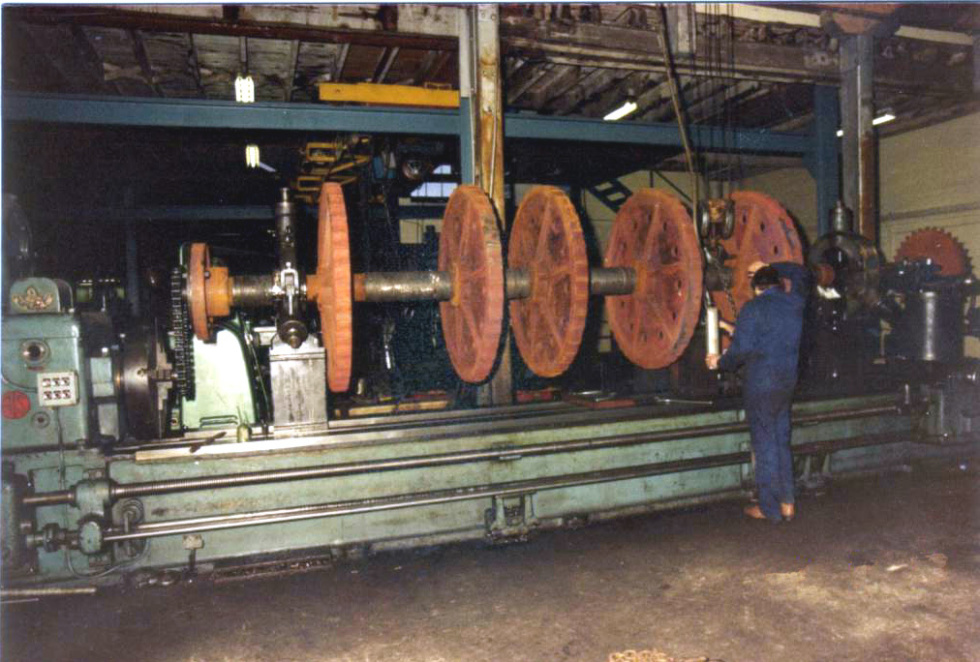

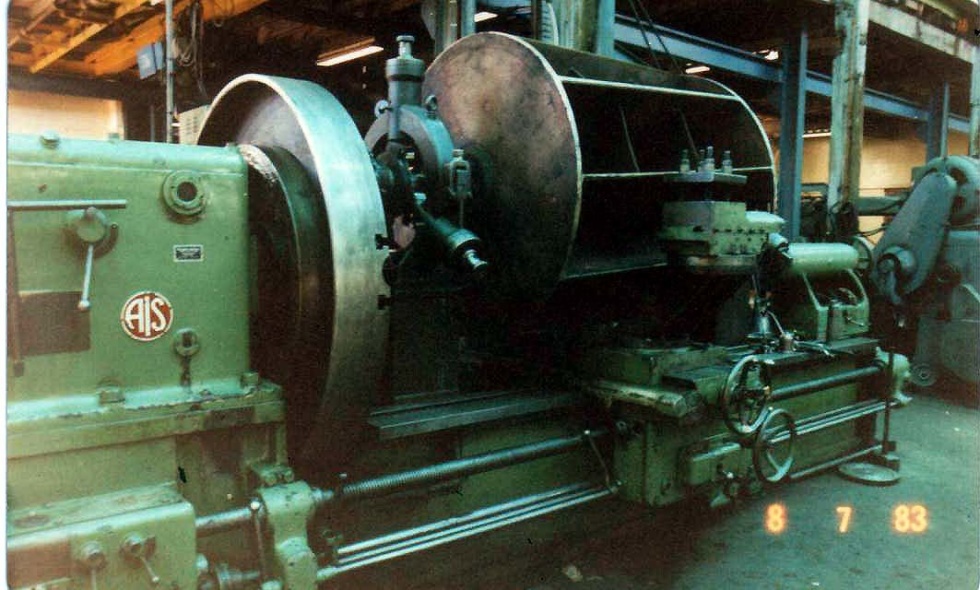

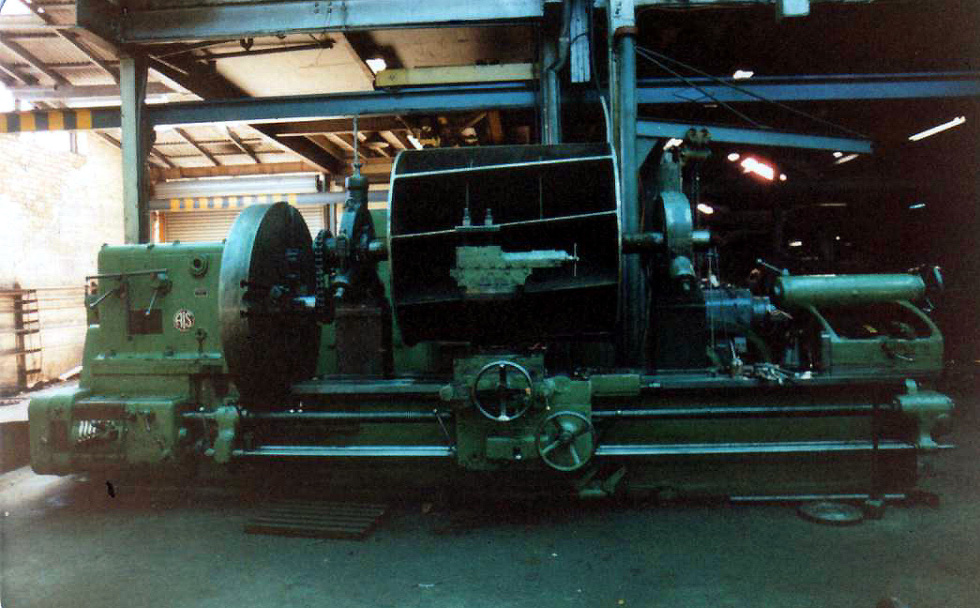

The trunnion shafts would wear on the bearing journals, this required building up the journal diameter, by welding with a 316 stainless steel overlay, and machining back to the required dimension. Quite a feat considering that the trunnion wheels were 1.5 metres in diameter and the shafts were 7 meters long. The longest lathe in the work shop was not capable to swing a diameter of such a dimension. Packing blocks were manufactured to go under the lathes steadies and a chain drive was rigged to the lathe chuck. With the tool post also packed to centre height machining proved quite successful.

The blower for the ship loader required similar measures to be undertaken. This would wear on the outer edge and required building up and machining to the required outside dimension.

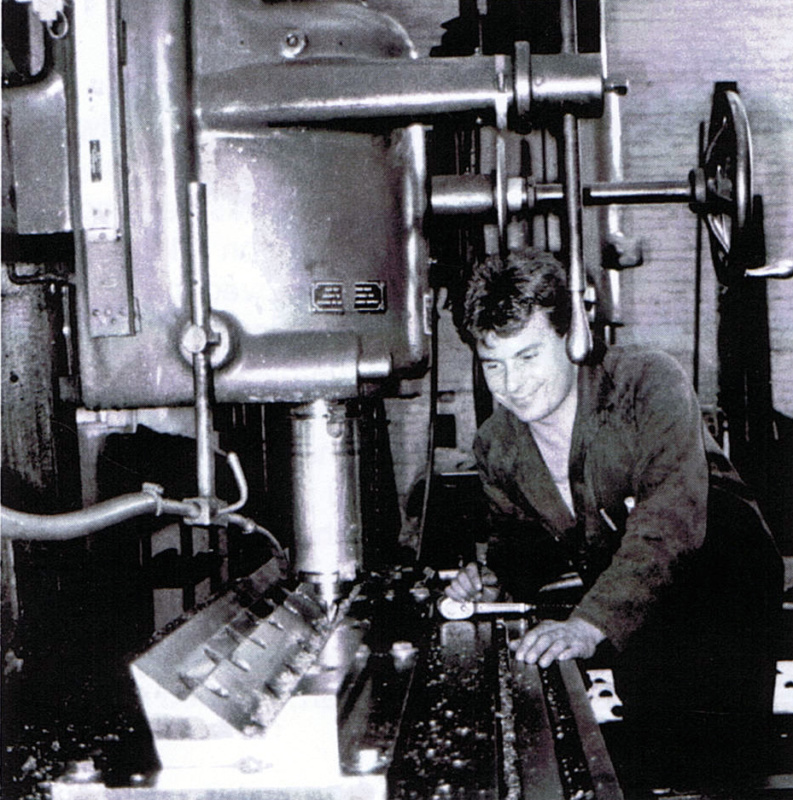

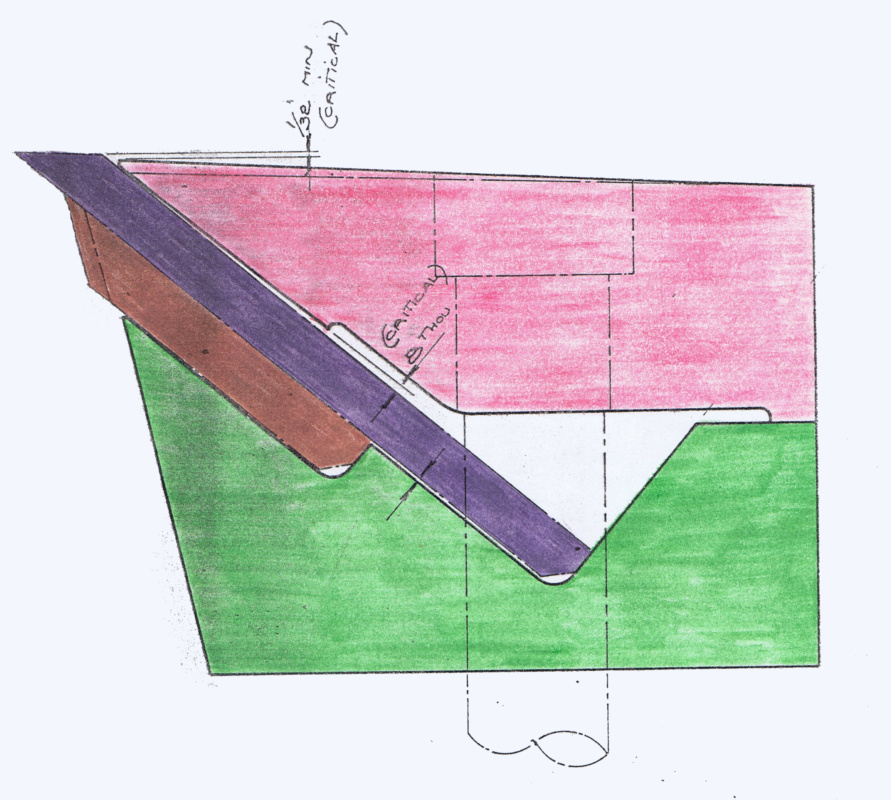

The machining of the Black Clawson 153 inch clamps and carriers and the 153 inch face plates were a large part of the work undertaken for the woodchip mills from the early 1980s onward. Glasgow Engineering supplied the castings which were cast in Melbourne from a high tensile 4140 material, and were then machined on a series of jigs and fixtures. Each of the Clamps and Carriers were tested and checked at the works prior to being dispatched to the chip mills by the mill engineer. The high accuracy and tolerances that had to be achieved on these were paramount. The faceplates were manufactured at the company works from 25mm mild steel plate. These were profile cut, drilled with a drilling template and then counter sunk to suit the holding bolts. It was very important that all the bolt heads on both clamps and faceplates were flush so that they would not create fines that could enter the stock pile.